The team at New United Goderich numbers more than 100, including staff at the company’s custom cabinetry shop in Burford, Ont.

It turned out to be a prophetic name choice when Blaine Field christened his first aircraft maintenance operation “Phoenix Aviation.” Founded in Brantford, Ont., back in 1993, the company’s name was chosen to signify transformation and rebirth. Indeed, Field was striking out on his own, after several years with his family’s aircraft sales, avionics and maintenance business.

Three years after it was founded, Phoenix began supplying maintenance services to the aircraft painting business. “We found they were working on more sophisticated aircraft than us, but they were only doing paint—they didn’t have the maintenance capability,” remembered Field. “So, in 1997, we got into the small aircraft painting business. That was our entry into the U.S. market, simply because you don’t see U.S. airplanes flying over four or five maintenance shops to come to Canada for work—but, you will see them fly over five paint shops to come to Canada, if they think they’ll get a better deal and a better quality paint job.”

The Embraer ERJ 135 and 145 (shown here) are regular visitors to the hangar at New United Goderich.

As any aircraft services provider will testify, the bird in the hand—also known as the airplane in the hangar—is always the best customer. For simplicity’s sake, an owner will commission other work to be done while their aircraft is in for painting. This realization prompted Phoenix Aviation’s first transformation in 1997.

Field renamed his company “Goderich Aircraft” and moved the painting arm of the business west to rural Centralia Airport—a former Royal Canadian Air Force training station (1942-1967) that was subsequently operated by the provincial government’s Ontario Development Corporation (ODC) as Huron Air Park.

“We had the Centralia facility but it was massive; you had to paint a lot of planes to make it worthwhile,” recounted Field. “At that time, we still had an operation in Brantford, but we came to a point where we all had to be together. So, that’s when we decided in 1999 to consolidate in Centralia and become a one-stop shop.”

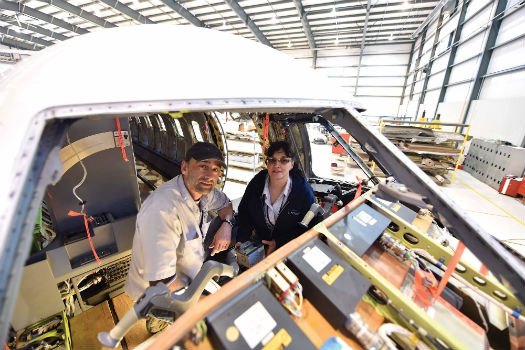

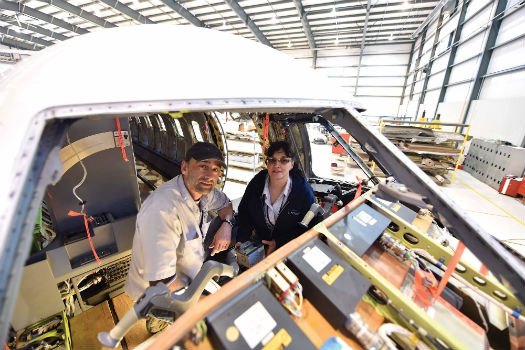

The avionics department, including Jerry Marshall and Connie Fischer, supports VIP modifications by installing in-flight entertainment, Wi-Fi, and satcom systems.

Initially, Goderich Aircraft rented more than 60,000 square feet of renovated hangar space from the ODC. The company pursued its plan to diversify its list of services.

“At first, we were known for our paint and interior work,” Field told Skies during a recent visit to Centralia. “Over the years, we brought up our maintenance and avionics services and perfected our ability to do whatever customers requested. Today, we’re a one-stop shop. We’re in the jet business and we offer the full spectrum of services: paint, interior completions and conversions, maintenance and avionics upgrades. We can do it all.”

“Doing it all” requires a lot of space. In 2007, the ODC put the entire airport and the Goderich Aircraft hangar up for sale, as the government moved to divest itself of airport assets. Field said there was no choice but to buy it all.

New United Goderich traces the roots of its aircraft paint shop back to 1997. As it branched into painting and began making a name for itself, the company began to attract more U.S. business.

“We had built quite a business here, but all of a sudden there was the potential that the airport could be sold,” he said. “So, we had to either move the business or buy the entire lot and move forward.”

With that decision, Goderich Aircraft acquired the airport and the hangar. Field renamed the facility James T. Field Memorial Airport in honour of his father, a former U.S. Air Force mechanic. With two long runways—5,012 feet and 4,400 feet—the airport can accommodate aircraft as large as the Boeing 757.

“We own the airport, so the negative is that we also own the costs to maintain the airport,” said Field, citing the company’s significant investment in maintaining asphalt, plowing runways and servicing lighting. “It’s an open private airport that is kept open for community safety reasons.”

The size of aircraft in the hangar at New United Goderich has steadily increased over the years. Today, the company works on a full range of jets, including the Bombardier line of business and regional aircraft.

The aerodrome’s out-of-the-way rural location (Centralia is about a 45-minute drive northwest of London, Ont.) is a double-edged sword. On the one hand, it’s off the beaten path, so it’s not the most convenient place for customers to visit. But, on the flip side, its remote setting tends to translate into less expensive operating costs that are often reflected in a customer’s final bill. As well, curious onlookers who want to photograph newly refurbished VIP aircraft are less likely to appear in Centralia, ensuring a greater degree of privacy for sensitive work.

To combat the negative aspect of their location, Field said it’s always been the company’s strategy to take its capabilities out to the customer, instead of expecting them to make the trek to Centralia.

Kimberly Kohnert, who has been with the company for a decade and is now vice president of sales, said it’s all about sitting in a plane with an owner to get a real sense of what they want. “When you get a call from a customer to quote a job, they might call four or five shops to get pricing; but, if you’re the only one who hops a plane to go and see them, you have a much better chance of getting the work,” she explained.

Attention to detail is evident in this Dornier 328 VIP lavatory completion.

Kohnert and senior sales associate and shareholder, Andy Orr, have successfully landed contracts for interior completions and conversions on Bombardier Challengers and CRJ200s, Embraer Regional Jets, Fairchild Dornier 328s, Gulfstream III, IV and V models, Boeing MD-87s and Boeing Business Jets (BBJs), among other types. Over the years, the size of the aircraft in the hangar has gradually increased.

Growth and Challenge

In 2006, Goderich Aircraft took on its first massive project, the 18-month-long VIP conversion of a McDonnell Douglas MD-87 for a high-profile head of state. “It took a long time, but we did everything in house from scratch,” said Field. Since then, the company has completed several similar workscopes, including a project for a second head of state. “That job involved paint and interior, building our own electrical harnesses, and designing and fabricating everything in house.”

New United Goderich is a”one-stop” destination offering a full range of aircraft services.

The client was so pleased with the finished product that he has since brought the aircraft back for scheduled maintenance checks to evaluate systems and components for serviceability and functionality. Although these checks could have been done at any number of locations, the customer chose to return to Centralia—proving that “it’s all about the relationships,” as Orr emphasized.

As its portfolio of services expanded, so did Goderich Aircraft’s physical footprint. In 2008, the company built a new 43,000-square-foot facility that includes offices, hangar space and supporting shop space. The new building was completed just ahead of what would be Goderich Aircraft’s biggest project ever in 2008—an “essentially green” $17 million completion of a Boeing 737 Business Jet (BBJ) for a Middle Eastern client.

This Gulfstream IV was fully modified for an overseas government.

“The Boeing Business Jet was our biggest technical accomplishment,” said Field, noting that the project took one year to complete. “It had everything you can imagine: a new floor plan with custom cabinetry; red, green and blue upwash/downwash LED lighting; satellite TV; a starlight ceiling that looked like the stars were out; every new technology; the full maintenance package; and full paint. The aircraft had the most advanced in-flight entertainment system available, as well as satellite phone, global system for mobile communications (GSM), Wi-Fi and fully electric lay-flat seats. The challenge was meeting the very specific design criteria demanded by the client; the extent of the design stretched our engineering and certification envelopes to the maximum.”

The team at Goderich Aircraft delivered a superb BBJ, but the job came at a high cost, catapulting the company into what Field candidly called the “perfect storm.”

“Because of that one particular job, Goderich Aircraft lost its ability to continue,” he said. “We had a spiking Canadian dollar on par with the U.S. dollar, and at one point it was even costing us 13 cents on every dollar. At the same time, we took on the BBJ project that expanded into a technical and human resources challenge. And then, the effects of the 2008 economic recession happened. It was the perfect storm—the dollar, the work—but, we did come out of it. We actually did finish and deliver a premier Boeing business product.”

The glossy veneer finish in the galley of this Gulfstream IV is achieved through the meticulous application of multiple layers of clear coat, which show off the wood grain.

Field likened the situation to that of climbing Mount Everest. “You know, I read that of those that don’t survive the climb, many tend to die on the way back down, not on the way up,” he said. “That was us. We hit our pinnacle, but then we died on the way back down.”

Goderich Aircraft had exhausted its resources while striving to turn out the BBJ during a rocky economic period. With more than 100 jobs at stake, Field said the management team faced a hard choice: “Either the company gets liquidated, or the company goes forward.”

New United Future

In September 2012, Goderich Aircraft ceased to exist. In its place rose a new entity, made possible by the acquisition of the assets by a new corporation, composed of a group of investors led by Field, along with majority partner New United Group (NUG) of Changzhou, China. NUG is a privately-owned conglomerate that specializes in manufacturing for several sectors, including railway transportation, CNC machines, wind generation turbines and aeronautics. The new corporation was named New United Goderich.

Once again, the company’s founders and executive team had come through a period of transition and rebirth. This time, the process had been painful and extremely rocky.

The management team at New United Goderich, with Blaine Field at far right.

“At the time, we were a broken company,” Field admitted. “We were all just happy to have jobs.”

Although it’s now operating as a new company with a new name, it’s largely been business as usual at New United Goderich. With the same executive team and Field continuing in his role as president, there has been a continuity of

leadership despite the presence of a new majority partner.

NUG’s acquisition of the Goderich operation was highly strategic. The company is one of the leading players behind the establishment of an aviation industrial park in Changzhou, near Shanghai, which aims to be a key centre for aviation manufacturing and related services. Field said NUG wants to duplicate New United Goderich’s business model and capabilities, but on a much greater scale.

“They want to take our years of experience and licences and technology, and prepare for the future in an industry that is in its infancy (in China) right now,” he explained. “We have hangars being built there now that can accommodate four times what we have here. For them, there is no better way than to step in with a company that has the experience across all spectrums of the business.”

Decades of experience and true craftsmanship are the hallmarks of the upholstery department. Leather is hand cut, with seats customized according to the customer’s preferences for foam density and contouring.

Field expects New United Goderich will benefit dramatically from the Chinese venture. He foresees that kits will be built in Centralia and shipped to China for assembly. The company will focus on developing greater capabilities for the future, such as Boeing 737 cargo modifications and engine overhauls.

In the near term, “We’ll be focusing on the CRJ, ERJ, and Dornier VIP market being pursued in China,” said Field. “When we develop a new product, it will be developed here. No matter what, we’ll always be the preferred supplier to our own joint venture.”

Recently, 22 young Chinese engineers spent 10 months at New United Goderich, returning home in December 2014. Each visitor was paired with a key member of the Canadian staff who was responsible for showing them the ropes.

As things progress in China, New United Goderich will be working to further expand its Canadian capabilities. Today, maintenance accounts for roughly 40 per cent of the company’s annual revenues, with interiors and modifications coming in at 30 per cent, and avionics and paint each representing about 15 per cent.

AME apprentice Margaret Cooke works inside a cockpit at the New United Goderich facility.

When Skies visited Centralia in March, the company was preparing to add a second full-time shift. Field said he expects to hire about 25 people this year; some of them graduates from nearby college programs.

When he looks back over the last few years, Field is proud of how far his team has come—and the challenges they have conquered together.

“Our egos were definitely bruised,” he admitted. “We were golden for years; we were growing like crazy and everything was wonderful. And then, all of sudden, we were going through years of not being able to pay people. It was pretty rough. But at the end of the day, I always remind myself, ‘There are 100 people employed here. Those hundred people have families, and no one had to sell their house and move because we’re still here today.’”

Field added that the company has worked hard to repair relationships with its vendors. At the same time, he acknowledged that its employees, customers and community are a huge part of New United Goderich’s recent success.

No matter what banner it’s operating under—Phoenix Aviation, Goderich Aircraft, or New United Goderich—Field said there’s one thing you can say about his team: “We never fail. We may hit obstacles, but we always rise up to deliver a fantastic product at the end of the day. We’re honest people and we do it right.”

When Blaine and his group of engineers first started out I was one of the first small aircraft to follow him . I was in charge of a few smaller aircraft and Blaine always kept them flying the way they were supposed to fly . Other companies played hard and fast with their customers wallets and aircraft , but Blaine took the high road and Never let us down . I am happy to have had a long association with them for a number of years .