Estimated reading time 6 minutes, 45 seconds.

Pratt & Whitney Canada made two announcements about its engines during the National Agricultural Aviation Association Ag Aviation Expo in Savannah, Ga., on Dec. 4.

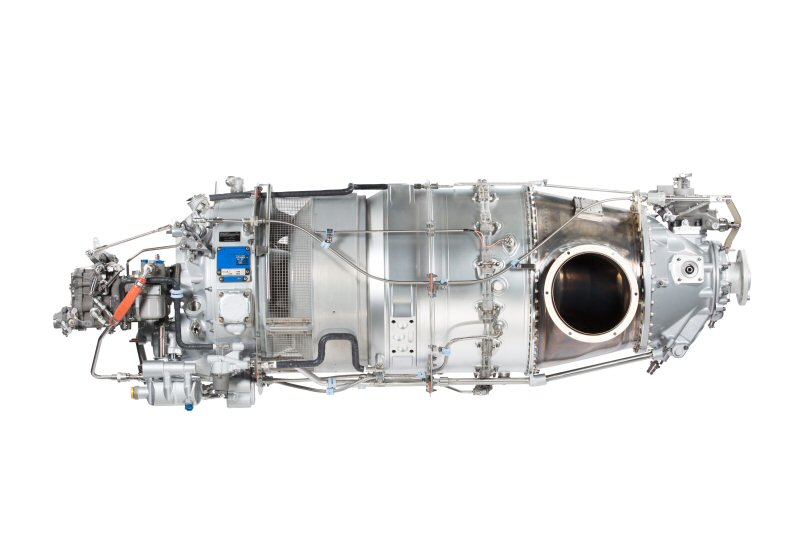

The company announced the extension of the basic time between overhaul (TBO) and hot section inspection (HSI) intervals for in-service and future PT6A-140, -140A and -140AG engines.

The TBO is increasing to 4,000 from 3,600 hours, while the HSI interval is extended from 1,800 to 2,000 hours.

These improvements will benefit general aviation operators by increasing flying time and decreasing maintenance costs.

“With the PT6A family, operators get much more than just an engine. We put our customers at the heart of everything we do, offering simplified maintenance and tailored service offerings to help maximize availability and minimize costs. As these latest extensions for the PT6A-140 series demonstrate, we’re committed to further enhancing performance and reliability so that our customers from all segments can spend more time flying and generating revenue for their businesses,” said Nicholas Kanellias, vice-president, General Aviation, Pratt & Whitney Canada.

The increased TBO and HSI intervals are made possible by the exceptional performance and reliability of the PT6A engine family, proven over more than 50 years, with 71 models and 128 aircraft applications.

These achievements have established it as a global leader in the general aviation segment and a benchmark for single-engine instrumental flight rules (IFR) revenue flights.

The PT6A-140 series is the latest addition to the PT6A family. The PT6A-140 entered into service in 2012 on the Cessna Grand Caravan EX, followed by the PT6A-140AG variant created for the agricultural segment in March 2015.

These engines have once again raised the bar for general aviation. The PT6A-140 series provide operators with 15 per cent more power and five percent better specific fuel consumption than comparable engines.

There are already over 450 engines in service around the world, which have accumulated an excess of 500,000 hours.

Across all families and applications, Pratt & Whitney Canada engines have amassed more than 820 million flight hours to date.

This track record, along with innovative digital technologies such as the FAST engine health monitoring solution and oil analysis technology, provides the company’s experienced personnel with exceptional insight into how, where and why customers fly.

They leverage this knowledge to provide world-class support to customers in over 200 countries flying a wide range of missions.

“Whether it’s extending the TBO and HSI interval or developing cutting-edge technologies that support more proactive and predictive maintenance, we’re dedicated to working with our customers to understand their needs and provide them with greater flexibility and tailored solutions that will improve their bottom line and give their business an edge,” said Kanellias.

Seamless entry into service

Pratt & Whitney Canada also announced roughly 25 PT6A-140AG-powered AT-502XP aircraft have been delivered to customers around the world since certification.

The entry into service (EIS) of the company’s latest engine for aerial application aircraft is progressing and as the application season in the Northern Hemisphere winds down, the engine has been performing very well.

“We are delighted with the performance of the newly introduced PT6A-140AG engine and the positive response we are receiving from customers,” said Kanellias.

“The PT6A-140AG is part of our latest generation PT6A-140 engine series and more than 450 such engines are in use around the world in a variety of applications. The PT6A-140 series has flown in excess of 500,000 hours with zero basic in-flight shut downs while delivering improved performance and operating economics, such as 15 per cent more power and five percent better specific fuel consumption than comparable engines.”

Located in Iowa, La., O’Brien Flying Service bought two AT-502XP aircraft for the 2017 spraying season. The two aircraft flew about 1,400 hours during the season.

“We estimate that having the two new AT-502XP aircraft this past season made our overall operation 12 to 18 per cent more efficient based on reduced fuel consumption and increased ferry speed,” said Dwayne O’Brien, owner, O’Brien Flying Service.

“Anyone who flies in the Gulf region knows that summer temperatures of 100 degrees or more with considerable humidity are common here; the PT6A-140AG has no power drop-off whatsoever under those conditions.”

Optimized for “hot and high” environments, the PT6A-140AG engine provides its full 867 shp capability up to temperatures of 111 F (44 C), effectively helping operators increase their productivity by maintaining full loads all day long.

With higher cycle limits on all rotating components than competing engines, the PT6A-140AG will continue to be a productive asset for any operator after other engines have been sent for overhaul.

“Our engineering team worked closely with Air Tractor during the aircraft certification process,” said Kanellias. “That collaborative approach was a significant driver of the seamless introduction of the AT-502XP at EIS.

“Both companies share a rigorous EIS process predicated on our many years of collaboration, which ultimately benefits our mutual customers.”

Air Tractor’s AT-502XP has been validated by aviation authorities for use in the United States, Canada, Brazil, Argentina, South Africa and Australia–all jurisdictions where the aircraft is now flying.

The PT6A-140 engine was originally certified in 2012 to power the Cessna Grand Caravan EX. Subsequent to the introduction of the PT6A-140AG engine variant created specifically for the aerial application segment, both leading aircraft manufacturers in the agricultural industry, Air Tractor and Thrush, have selected the engine for their 500-gallon aircraft.

The National Agricultural Aviation Association’ Ag Aviation Expo, runs until Dec. 7.