Estimated reading time 12 minutes, 5 seconds.

It used to be called the suggestion box, a place for employees to leave their best ideas to improve the company, or at least the coffee. Today, workplace idea generation often has a more competitive vibe, drawing on the example set by television shows that encourage people to pitch new thinking about products, services and processes to senior executives.

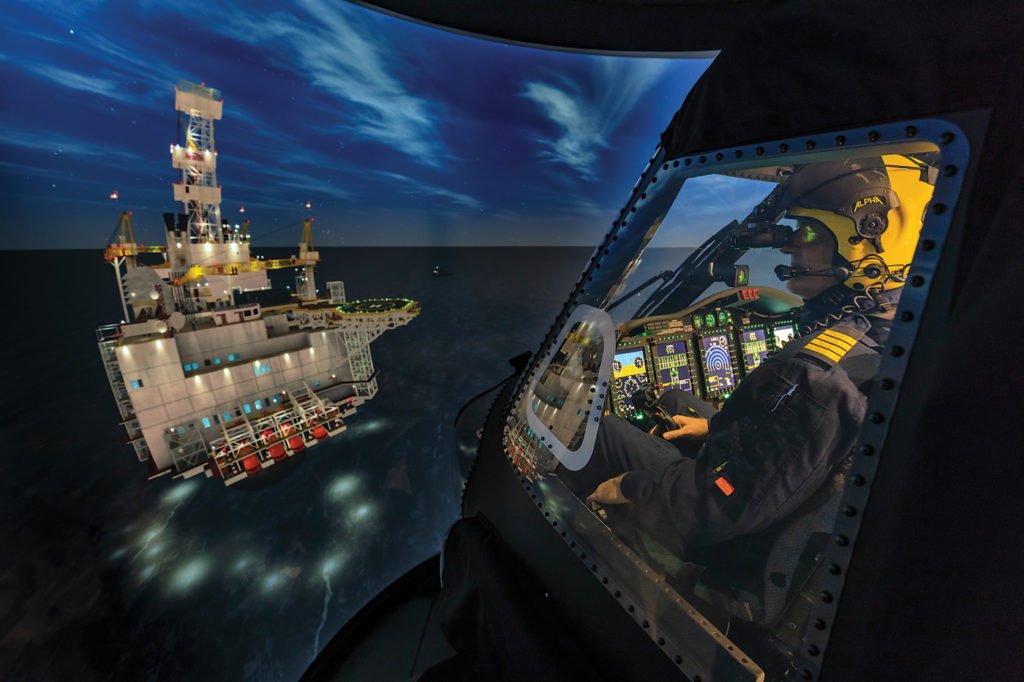

Count CAE among the many companies now trialling this approach. The Montreal-based modelling, simulation and training company is widely recognized as one of the most innovative enterprises in aerospace, changing forever the way pilots and instructors are trained. But since 2012, it has also dramatically shifted the way it sources ideas, changing from a closed innovation process in which senior executives set the priorities, to a more open approach that has sought to tap the creativity of all 8,500 of its employees.

To avoid a free-for-all and keep the ideas channelled with strategic priorities, CAE that year launched Innovation Challenges to its entire workforce, inviting suggestions along three lines of inquiry that Marc St. Hilaire, vice-president of technology and innovation, admits are the sorts of perplexing problems that keep him awake at night.

“I believe innovation can come not only from engineering employees, but from everybody who touches some part of the process or product,” said St. Hilaire, an aerospace engineer with 32 years of experience in the sector, including 11 with CAE.

“Innovation could be in the product itself, or within the processes we use to build it, or in the way we go to the market and advertise.”

Until this year, the previous four Innovation Challenges typically generated around 100 ideas. Those were shared on an internal web portal to which employees could contribute their thoughts. Stories would soon develop around an idea as people added new dimensions or cast a positive or negative vote.

Perhaps because CAE is marking its 70th anniversary or because St. Hilaire immersed himself in a highly creative promotional video and campaign to employees, this year the challenges drew over 200 responses to four themes: cloud computing, cyber technology, new training media, and the environment. “This year was exceptional,” he said. “We touched probably 100 per cent of the company.”

The ideas were grouped into common threads, and in June each group presented their ideas before a panel of senior managers, trying to persuade them to make the ultimate investment. If previous competitions are any indication, more than a dozen of those ideas could find their way into future products and services.

In past editions, the 100 proposals have typically been boiled down to around six or seven that are worth taking to the lab for feasibility testing. A few have then gone on to prototyping, and one or two have then survived the business test: can CAE market it?

“I am proud to say a significant number of those tested ideas have migrated through the journey and you can find them in our products,” said St. Hilaire. “The best example is the new instructor station that is in our latest product. That’s the result of one of the earlier challenges where we asked people, ‘How do we ease the load on the instructor and modernize his/her workstation?’ ”

CAE’s approach to utilizing big data to deliver a next-generation pilot training system has its origins with the Innovation Challenges, as does a new product line that capitalizes on the emergence of augmented reality. In January, the company introduced a health care training solution that integrates Microsoft HoloLens to help train doctors and nurses in ultrasound and catheter insertion on a mannequin.

“The challenges have paid off big time,” said St. Hilaire.

Complete Training Partner

CAE’s broad call for innovation is related, in part, to a corporate change that began two years ago when the company shifted its primary focus from manufacturing training platforms and simulators to being a full-service training partner. Along with the shift has come an increased need to find better ways to leverage the full scope of digital technology.

Founded in 1947 as an avionics repair company, Canadian Aviation Electronics by the 1980s was breaking new ground with the U.S. Federal Aviation Administration on the certification of flight simulators, an innovation that transformed both pilot training and flight safety.

By the early 2000s, the company had adapted the software of its full-flight simulators to more desktop-like applications, a suite of two- and three-dimensional devices it called Simfinity, which significantly reduced the training footprint and allowed pilots to practice procedures and specific systems before entering the more expensive simulators.

Beginning a decade ago, CAE then delivered similar tools in a web-based service, allowing pilots to download and view and rehearse approaches and landings to hundreds of airports all over the world. At the same time, the company also began offering modelling and simulation technology to aircraft manufacturers like Mitsubishi and Bombardier.

“We have adapted our full-flight simulator and transformed it into an engineering development test bench to test their systems and help design and build their aircraft,” said St. Hilaire.

While CAE continues to advance and deliver simulators worldwide–it recently confirmed contracts for full-flight simulators for Air India and Japan Airlines, among others–the announcement in June of a new CAE training facility with Korea Airports Corporation at Gimpo Airport in Seoul for the pilot training of five Korean carriers is more indicative of its current focus as a complete training partner. Consequently, the company is evaluating how best to deliver pilot and aircrew training to a generation more accepting and expectant of technology.

“We have intensified our efforts to focus our brain power and innovation capability on mechanisms to deliver training in a very modern way,” said St. Hilaire. “Instead of the traditional classroom printed material, we’ve started to look into all of the modern technologies to deliver training, and to leverage digital technology, big data technology, and web technology to provide a training experience that is truly 21st century.”

One example, which emerged from the first Innovation Challenges theme on big data, is CAE’s next-generation training, an employee idea that has flourished into a system CAE launched with AirAsia and began validating last fall. The concept harkens back to the primary education experience of many students, where little record of their actual performance remains beyond test scores, a grade and a few comments on a report card.

Most pilot training, too, has fallen short of capturing the full picture of a pilot’s training journey. The record may show satisfactory performances in groundschool, and passing marks on flight instruments, full simulators, and live flying, but it misses a lot of the contextual data about strengths, weaknesses and overall performance.

Tapping into the data generated by all those systems, next-generation training aims to employ collection and analysis techniques to provide insight into a pilot’s skills and help improve the quality and efficiency of training.

“You can’t improve on your courseware, on your performance if you don’t have a record of the good points and the weak points,” said St. Hilaire. “This is your training record that stays with you. We are measuring the training journey in a numerical way, from the beginning to the end, as you go through each training event and each objective. We are measuring your knowledge, your performance, and your proficiency. You can quickly start to visualize where you are with your peers. You can also see if your courseware is poorly designed, if it has a chokepoint where students are tripping.”

The data-driven approach will improve the experience not only for individual pilots, but also for instructors and training managers with large fleets, who can quickly identify which approaches produce the best results. It should also assist aviation regulators by providing a means to measure efforts to improve aircraft and passenger safety.

“All of this new data and web technology gives us the capability to precisely map the training journey and take actionable decisions on it,” said St. Hilaire.

Training Reimagined

For this year’s edition of the Innovation Challenges, CAE sought ideas to expand next-generation training, asking employees to reimagine training media by thinking outside the current training constructs of the classroom, printed material, partial task trainers, and even full flight simulators.

“I call that the traditional training footprint,” said St. Hilaire. “New training media includes augmented reality like the Microsoft HoloLens glasses or your personal smartphone, which is a media to push content back and forth between a training organization and an individual. We [wanted] to stimulate the employees to look around at all the media they carry. There’s been a real revolution. Your smartphone is now a window between you and the rest of the world that is being leveraged to push content.”

CAE also invited employees to look more critically at the environmental footprint of the company and its products. Simulators remove thousands of hours of live flying and significant efforts have been made to reduce or change the use of chemicals and heavy metals in its products, but St. Hilaire is looking for other innovations. “We are already pretty green. Our product is green, our business is green, but now we are looking ahead. What’s next?”

It is far too early to know which ideas will survive the lab, but already St. Hilaire is considering possible themes for 2018, challenges such as artificial intelligence (AI) and autonomy, especially as more unmanned systems enter the airspace.

“Artificial intelligence is going to disrupt our life in ways that we have not even imagined so far,” he predicted.

Perpetually on the hunt for the next disruptors, St. Hilaire and the company’s technology team are regular attendees to the technology events of CAE’s core business lines of aerospace (civil, defence and security) and health care. But they can also be found among the booths and demonstrations of the Consumer Electronics Show and South by Southwest. Whether it involves participating in local innovation clusters or supporting academic research, the goal is always to try and understand what might change the training paradigm.

“I’m a big believer that innovation will come from the intersection of industries that normally you wouldn’t think of working together,” he said. “A traditional sector like aerospace can find a lot in the IT or gaming sectors, or even the medical sector. Those industries are pushing innovation that nobody has talked about.”

Chris Thatcher is an aerospace, defence and technology writer and a contributing editor to Skies Magazine.